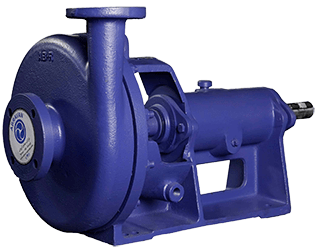

Horizontal centrifugal pump with a screw chamber, one floor, single suspension impeller, separate motor, central single suction and in terms of dimensions and performance according to Din24255. The pump impeller is dynamically balanced and the shaft is sealed by a mechanical seal or graphite tape.

The pump shaft is protected by a replaceable chrome-nickel steel bushing.

The radial and axial forces acting on the pump shaft are borne by two greased ball bearings located on one side of the impeller. Oil lubrication is also possible at the customer’s request.

These pumps are designed so that the surface and the bearing base can be easily opened by the electric motor without removing the chamber from the piping system.